A Lintec CSM4000HS20-SE asphalt batching plant, featuring a maximum output of 320 t/h, has helped a major Chinese contractor meet the pressing demands of several prestigious projects over the past 18 months.

Based in China’s eastern Zhejiang province, Ningbo Heng-Shun Traffic Engineering Co Ltd took delivery of the second-largest containerised asphalt plant in the Lintec line at the end of May 2019. By the middle of June, thanks to the ease with which its modular structure can be assembled, the plant was already in full-time operation, typically mixing over 3,000 t of asphalt during a standard 10-hour shift.

Materials from the plant are delivered to a host of the contractor’s regional projects. This has included the phase four expansion project of Ningbo Lishe International Airport as well as numerous surrounding highways.

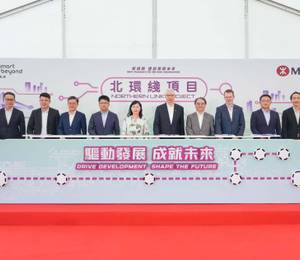

Ningbo Heng-Shun selected the Lintec plant back in 2019 after travelling to the construction site of the Hong Kong-Zuhai-Macau bridge, where another CSM4000 had just completed the job. Seeing the performance of the plant on this high-profile, heavy-duty project sealed the deal for Ningbo Heng-Shun’s leadership.

The company’s plant manager, He Gangfeng, said there were also several design features that really appealed to the organisation: “In terms of efficiency and consistency of the final product, the Lintec model has outperformed brands we’ve previously used. The operating system provides very precise weighing of the aggregate and bitumen ratio. This is a unique feature for us and has already saved us a significant amount of bitumen.”

He added, “We also opted for corrosion resistant paint as an option, and that has really given us effective environmental protection against the humid and often harsh climate of the East China Sea coast. This saves us a lot of money as other plants would always require third-party cover.”

The requirement for a plant capable of mixing an average of 300 t/h wasn’t the only persuading factor for Ningbo Heng-Shun. Environment-friendly performance was also crucial as the plant is based close to city centre areas. To meet these needs, Lintec’s standard pollution control unit, which recycles dirt particles into reclaimed filler rather than emitting them into the air, has proved an essential feature.

Lintec’s ISO-shipping container structural design provides further advantages for owners such as Ningbo Heng-Shun through its simple, low-cost transportation and assembly. In addition, the company’s customer-centred commissioning process ensures work begins as soon as possible after delivery, according to Tony Liu, CEO of Lintec & Linnhoff China Ltd.

“Our CSM batching plants are easier to assemble than competing models, due in large part to their high level of factory pre-assembly,” explained Mr Liu. “But we still ensure all our installations quickly reach maximum operating efficiency. Before delivery, we bring future operators to our factory to train them in T&E (Testing & Erection), before sending one of our own engineers to the jobsite for full supervision of erection and commissioning.”

Once a plant has begun operation, a Lintec engineer offers on-site technical support to ensure optimum production, with full operator training also provided (as was the case for Ningbo Heng-Shun). Lintec engineers are also able to log-in to the operating system of any unit, to provide 24/7 remote technical support. This allows them to make rapid diagnoses of any issues to ensure the plant continues to operate at maximum efficiency.

Ningbo Heng-Shun Traffic Engineering is one of the largest contractors in Zheijang province. It works directly with a number of state-owned-enterprises in China, supporting major infrastructure and construction projects.